The surface of stainless steels is covered with a thin oxide film which protects the material and makes it corrosion resistant. The oxide film acts as a barrier for the transfer of carbon and/or nitrogen atoms to the metal and prevents straightforward surface hardening of stainless steels. Now researchers at DTU Mechanical Engineering have launched a patent applied for process that enables an effective removal of this protective oxide layer, which then allows a fast and efficient surface hardening of stainless steel and titanium alloys.

A new company in charge of the technology

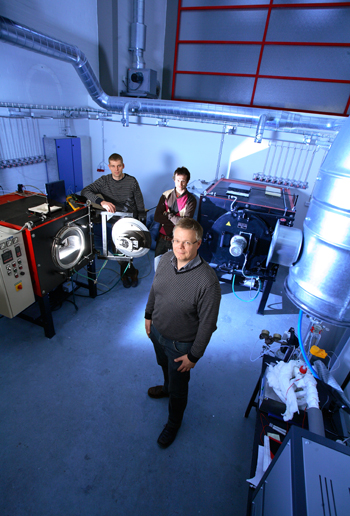

At DTU Mechanical Engineering the researchers behind the invention are testing the method on various items and on a variety of products and materials. Professor and Section Head Marcel Somers, Senior Scientist Thomas Christiansen and PostDoc Thomas Hummelshøj have established the company Expanite based on the patented applied for process and they use modified annealing furnaces to apply the method. Several companies are involved in testing the suitability for their products to the Expanite process in a Proof of Concept project granted by the government in order to examine whether this new technology may be used to improve their product features. Marcel Somers explains: “The Expanite process is highly generic and functions on ordinary and stainless steels as well as on titanium. Compared to other processes, the treatment time is competitively shorter. Moreover, since our process is a gas process the implementation technology is widely available. We are now busy testing the technique on all kinds of products. Food processing, paper fabrication and medical applications are just a few examples where production equipment has to be corrosion as well as wear resistant. Our process is likely to be of great interest to numerous companies worldwide and the establishment of Expanite makes it possible for us to assist such companies on commercial terms. Our process is more versatile, faster and cheaper than the current alternatives. ”

The home appliance industry is one of the largest consumer product industries in which stainless steel is widely used to prevent corrosion. However erosion of home appliances is a problem because it deteriorates their appearance. Examples are refrigerators, stoves, sinks, kitchen tables, wash basins, cookware and cutlery.

Revolution in surface hardening methods

Many stainless steels meet the need for corrosion resistance but their relatively low hardness often results in accelerated wear and materials loss. Since these materials cannot be hardened by conventional heat treatment without reducing corrosion resistance it is common to make design allowances for repair and/or replacement of equipment, even though this is far from the ideal solution. PostDoc Thomas Hummelshøj is appointed as the first CEO of Expanite. He explains that even before the Expanite technology it was indeed possible to achieve surface hardening of stainless steel. However the process was restricted to relatively costly niche products such as key components in nuclear power plants, aerospace and fasteners in marine and defence equipment, all expensive and critical parts which do not tolerate failing. He says: “It was complicated, expensive and time consuming to remove the protective oxide layer covering the stainless steel which prevents a straightforward method for surface hardening. Delivery time for the treatment was anywhere from 3 weeks to several months and items with complicated topology were almost impossible to process. With our new technology you just have to add the right gas and use the right temperature and furthermore you are able to treat any kind of subject within a few hours.”

Senior Scientist Thomas Christiansen has been working on the process for several years first as a student at DTU Mechanical Engineering and since as a member of the research staff at the department. His concluding remark: “It is a great relief to reach Proof of Concept after all the time and effort. Our patent pending process goes behind and further than the technology previously used. The Expanite treatment involves an effective removal of the protective oxide film on top of the stainless steel. This allows an incorporation of carbon or nitrogen atoms in the underlying metal within comparatively short treatment times. After ended treatment the protective oxide layer is re-established automatically. The result is a resistant and practically scratch free surface. It really is a breakthrough in gaseous surface engineering and a complete revolution in the way surface hardening of stainless steel is made. Apart from this we are worldwide recognized for our generic research work in this field, which has been published in the last 6 years. A very good example that fundamental research and innovation go along.”