Outstanding example of interdisciplinary approach to research involving studies of the production of polymer micro components.

Some of the smallest components of hearing aid systems or of the ultra-thin channels on micro fluidic systems used for e.g. analyzing blood are precision-moulded. These micro components are less than one millimetre in size and include features down to the micro- and nanometre scale. For three years their production was at the heart of Italian researcher Guido Tosello’s Ph.D. project ‘Precision Moulding of Polymer Micro Components’.

The project comprises studies of mechanical construction, materials technology, process and production technology as well as geometrical metrology and process modelling.

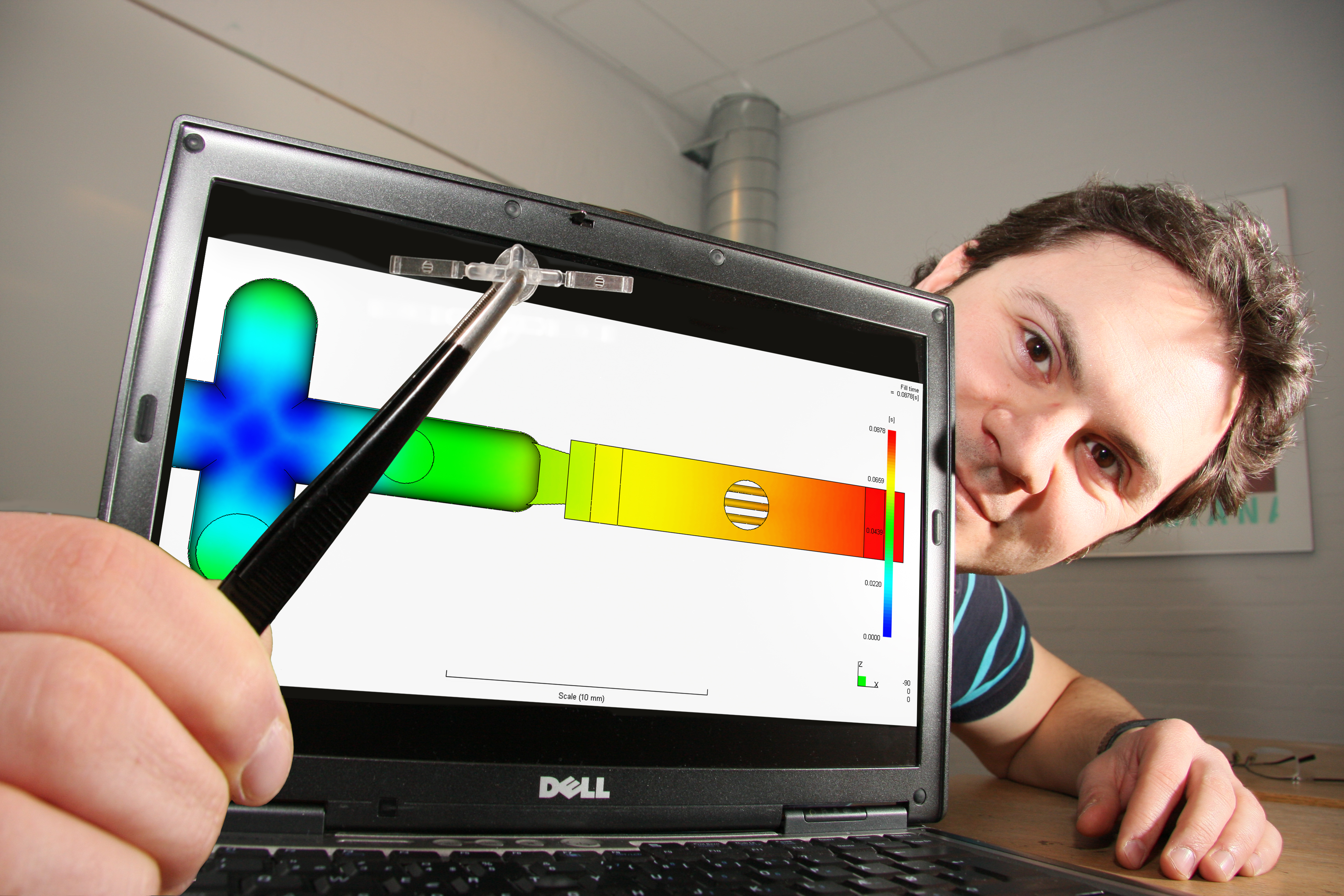

“The present work contains a study concerning polymer micro components manufactured by means of the micro injection moulding (μIM) process. The overall process chain was considered and investigated during the project, including part design and simulation, tooling by micro machining, process analysis, part optimization, quality control and multi-material solutions”, says Guido Tosello.

A new approach developed: process analysis and part optimization

A series of experimental investigations were carried out on the influence of the main μIM process factors on the polymer melt flow within micro cavities. A new approach based on coordinate optical measurement of flow markers was developed for the characterization of the melt flow.

“In-line pressure measurements were also performed to characterize the process in terms of injection time depending on the process factors. The process quality in terms of repeatability was assessed over a broad range of the process factors. The results show that the main influencing factor on the micro injection is the injection speed”, says Guido Tosello.

Design of experiments and atomic force microscopy were employed to characterize depth and width of surface defects depending on μIM process factors.

“Experiments showed that the temperature of the mould, the injection speed and the weld lines position with respect to gate location were the most important parameters affecting the defects of the micro injection moulded parts. Optimization following the analysis leaded to a decrease of defects dimensions of at least 35 %”, says Guido Tosello.

New methods implemented: micro injection moulding simulation

New methods for the validation of commercially available injection moulding simulation software were developed and implemented during the project.

“The importance of material characterization at micro scale, of machine’s dynamic behaviour implementation and of micro geometry modeling was shown in a quantitative study”, says Guido Tosello.

International partners

A round robin among European partners of the Network of Excellence 4M (Multi-Material Micro Manufacturing, www.4m-net.org) was performed in order to assess the performance of newly developed hybrid technologies for micro tooling.

A new manufacturing route was established during the Ph.D. project including micro electrical discharge machining (μEDM) of silicon, selective etching and electroforming.

“The tool produced using the new process chain showed significant advancements in terms of miniaturization, accuracy, high aspect ratio, multi-scale integration and surface finishing characteristics. The tool was tested on an injection moulding machine for the production of polymer micro fluidics systems”, says Guido Tosello.

The research work during the Ph.D. project was carried out also in collaboration with the Department of Microsystems Engineering (IMTEK) at the University of Freiburg (Germany) and with the Department of Innovation in Mechanics and Management at the University of Padova (Italy).

Won DTU award

On 31 October 2008, Guido Tosello was delighted and honoured to receive the DTU’s “Best Ph.D. research work 2008” award for his Ph.D. project on precision moulding. His Ph.D. project was selcted as the best of the year. Guido Tosello’s project was chosen because he has demonstrated excellence in research and extremely high productivity. He documented his findings in 27 international publications and was cited as principal author in about half of these.